The oil sending is at the rear of engine just below the valve cover at right side of engine.

I think a screw with phillips head on the wire. Be very carefull when tighting. Make sure u check oil tank is staying full while running and revving.

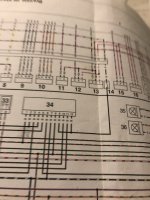

There r ways of checking the wires. Wire checking may be complicated and best done after changing sender.

Any pieces u can leave off in order to disconect wire would be good.

Reprase in order to check wires

The wire has to come off sensor

I dought if anyone has experience with the code u have it might just disappear when u fix the sendor

)

)